STAGE II: PRODUCTION

STAGE II: PRODUCTION

The designing stage has completed!

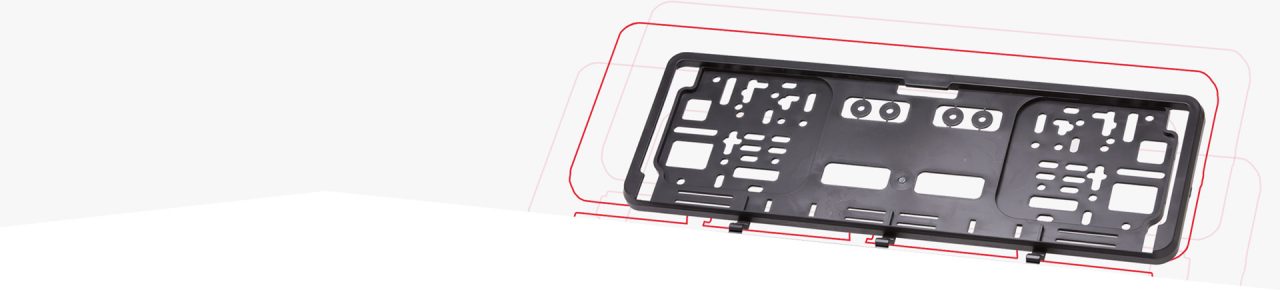

The production of your order can now start. We are very well prepared for this stage: we set solid foundations, excluded all the spotted defects, minimized the risk of failures and optimized – so far, on paper – the entire production process.

Now, the time has come to switch from theory to practice. In this tab, we will cover the production process of your element in detail.

ADDITIONAL SERVICES

There is still more to that! Besides the construction of injection moulds necessary for the production at our site, we offer tooling services externally. We manufacture components for stamping dies, punching dies and parts for all kinds of machinery and equipment. It is possible thanks to our extensive machine park and experienced team who keeps up with the changing world of technological possibilities.

Our additional services include:

- CNC milling,

- CNC milling and turning (with an Y‑axis lathe),

- turning,

- grinding,

- engraving,

- drilling,

- 3D printing.

We process the following materials:

- aluminium,

- bronze,

- graphite,

- MDF,

- brass,

- steel,

- plastics.

STAGE II: PRODUCTION

Go back to the previous stage