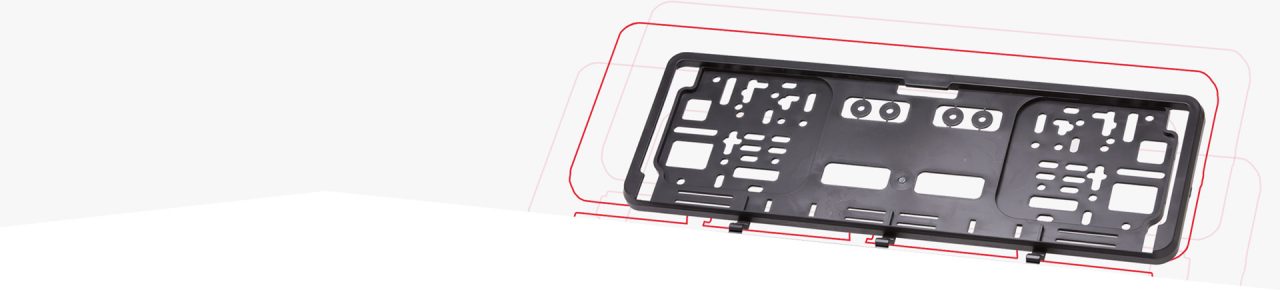

Stage I: designing

Stage I: designing

At Gieros, the designing stage always precedes the production. Even if you already have a finished design, we will analyse it to check whether it can be optimized for production. We believe that preliminary designing assumptions determine the entire subsequent technological process, its effectiveness and profitability, as well as the durability of the injection mould and the final quality of moulded pieces. At this stage, we run economic and technological analysis of your order, we choose the material and the method of production of the injection mould, build prototypes and prepare the documentation. It ensures that the actual production will run smoothly.

Economic analysis

of the element production

If you contact us presenting your idea or project, we will offer you more than one price calculation and one technological strategy (which is common at the competitors’). We can offer you two different calculations (or more, if you need), so that you can choose an option which fits you best and autonomously decide how would you like to spend your money.

We will not impose you anything. Our offer is neither definite nor unobjectionable. You will not hear from us: “Your mould will cost you x amount and will produce x pieces”. Instead, we will ask you: “What are your business plans? How many pieces to you need? How much would you like to spend on the mould? How much should one moulded piece cost?” We will prepare a calculation on the basis of your responses to the above (and the factors listed below).

The amount of your investment depends mainly on the tool production costs which depend on:

- the planned construction of the element,

- the quality and functionality requirements for the element,

- the estimated production volume,

- the size of the tool, i.e. the number of moulding cavities,

- the tool material,

- the durability of the tool,

- the deadline for the pre-production stage.

The above parameters are flexible, and the production of the plastic element can be adjusted for the best alignment with your assumptions and expectations.

The two below cost calculations, all for the same project, are to help you understand it better*:

Injection mould multiplicity

8

16

24

Injection mould price

EUR 7,200

EUR 10,250

EUR 14,830

Price per element (piece)

EUR 0.076

EUR 0.061

EUR 0.045

*calculated from PLN to EUR based on the PLN to EUR exchange rate as of 02.06.2022

As you can see, the production of one single piece can be tackled in a few different ways and the costs can be distributed flexibly. Now it is up to you which option to choose.

Focus on your priorities.

- Do you want to set foundations for a large-series production of your element, and, consequently, you want the injection mould to be as durable and possible, and the cost of production per piece to be the lowest possible?

- Do you plan to launch a limited edition of your product, and you are less bothered about the durability of the mould and the cost of production per piece than about the investment amount?

- To give you a more vivid example: do you need a tool made of steel which will produce 3 million pieces worth 1–2 grosze each? Or do you prefer to have a less robust, aluminium mould which will be durable enough to produce 50 thousand pieces worth 1 zloty each?

- Are you able to pay for an expensive tool with high return on investment thanks to a low cost per produced piece?

- Or do you have a limited amount of money for the launch, so you would rather have a cheaper tool which will help you earn for a better tool in the future?

- Or, instead, do you want to test your business idea first without investing much, regardless of the amount of your capital?

There are several options, and one calculation only is not enough to present them all.

We recommend you to ask yourself all the above questions and, based on the real amounts that we will provide you, analyse your plans, verify your capabilities, assess the risk etc., and, finally, choose the option that suits you best.

At Gieros, you choose. You take part in the decision-making process and have a voice regarding the price of the injection mould and per moulded piece. We are here to advise you according to our best knowledge without imposing you how much to spend.

STAGE I DESIGNING

GO TO A DIFFERENT SAGE