Stage I: designing

Stage I: designing

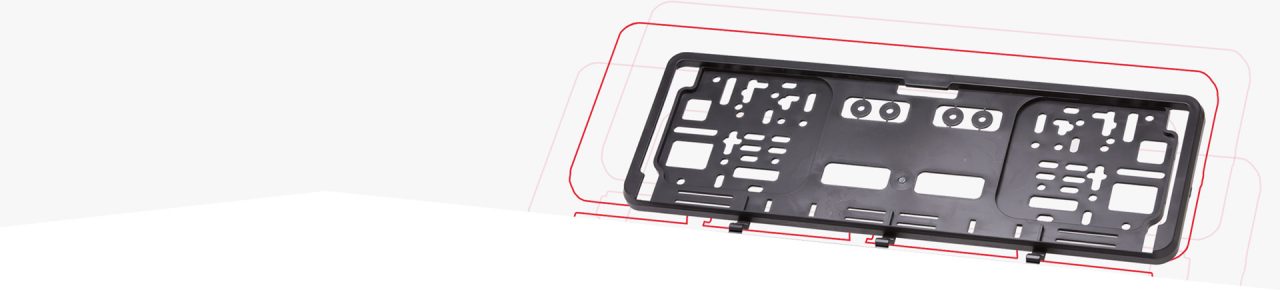

At Gieros, the designing stage always precedes the production. Even if you already have a finished design, we will analyse it to check whether it can be optimized for production. We believe that preliminary designing assumptions determine the entire subsequent technological process, its effectiveness and profitability, as well as the durability of the injection mould and the final quality of moulded pieces. At this stage, we run economic and technological analysis of your order, we choose the material and the method of production of the injection mould, build prototypes and prepare the documentation. It ensures that the actual production will run smoothly.

CHOICE OF MATERIAL

Another matter to be determined during the designing stage is the selection of the appropriate material from which the ordered product is to be made.

Should your element be hard or soft? Flexible or rigid? Transparent or in a specific colour? Resistant to scratches, mechanical damage, particular physical conditions (e.g. high temperature, UV light) or chemical substances (e.g. acids)? Should the material be decorative or technical? Should it be approved for contact with food, or maybe aromatised?

While choosing the material for your design, we will consider all the above. It is important that the material meets the requirements of the design, and that the manufactured piece made of it has the specified properties and is suitable for the intended function.

The aesthetics is, of course, also important: the shape, the colour and other visual effects, such as matte or shiny surface finish.

Thanks to the long-term relationship with recognised producers of colouring concentrates, we can dye the material for your order virtually any colour from the Pantone or RAL palette. It depends on your vision.

At our company, we process the majority of thermoplastic materials available on the market.

These are, among others:

Amorphous plastics:

- acrylonitrile butadiene styrene (ABS),

- acrylonitrile styrene acrylate (ASA),

- styrene acrylonitrile (SAN),

- polystyrene (PS),

- high impact polystyrene (PS / HIPS),

- polycarbonate (PC),

Semi-crystalline plastics:

- polyamide (PA),

- low-density polyethylene (LDPE),

- high-density polyethylene (HDPE),

- polymethyl methacrylate (PMMA),

- polyoxymethylene (POM),

- polypropylene (PP),

Elastomers:

- styrene-butadiene-styrene (SBS),

- styrene-ethylene-butylene-styrene (SEBS).

The list of plastics produced by humans is, and will probably be, endless. We cooperate with world-class producers and advisers for polymers, such as BASF, Baser, Polyman, as well as local suppliers. So, even if you are not convinced about any of the above listed materials, we can find another one or produce a blend with desired properties for you. Your design will determine that.

We are open to your suggestions about the choice of the material, however you can also count on our professional advisory, both regarding the functionality and the aesthetics of the material. We offer you all the best we have for you to be satisfied with the final product and to enable you to carry out your ideas and plans.

STAGE I DESIGNING

GO TO A DIFFERENT SAGE