Stage I: designing

Stage I: designing

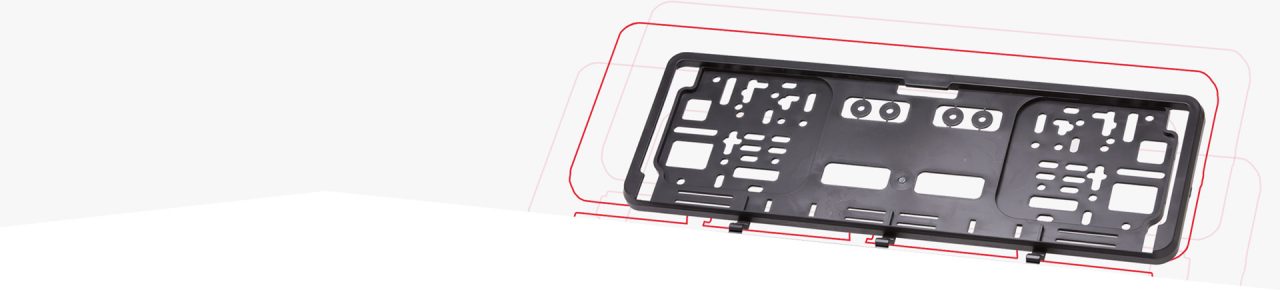

At Gieros, the designing stage always precedes the production. Even if you already have a finished design, we will analyse it to check whether it can be optimized for production. We believe that preliminary designing assumptions determine the entire subsequent technological process, its effectiveness and profitability, as well as the durability of the injection mould and the final quality of moulded pieces. At this stage, we run economic and technological analysis of your order, we choose the material and the method of production of the injection mould, build prototypes and prepare the documentation. It ensures that the actual production will run smoothly.

FAST PROTOTYPING

The last part of the designing stage is the production of the prototype of the ordered element. It is a crucial phase, when we can verify whether our assumptions were correct and whether the production can be further optimised.

Thanks to this professional approach, you can already know whether we interpreted your suggestions correctly and whether the visual and functional aspects of your element correspond to your concept and vision.

Besides, it goes without saying that you can participate in the preparation processes and raise your remarks and suggestions during this whole time. All in all, paper or computer visualisations cannot equal to the possibility of seeing and touching the real model. If you liked the prototype, you can ultimately approve the action plan we prepared for you. Once you do that, the construction works will start.

We can offer you a few prototyping methods which enable a very fast preparation of the element with expected or similar to expected parameters. These are:

3D PRINT

It is a technique for fast production of three-dimensional objects. Thanks to the available technologies, the prototypes produced with this method do great at visual and functional tests. It is also a cheap method of elimination of potential construction errors and assessment of the element design.

PRODUCTION OF A SAMPLE ELEMENT WITH INJECTION METHOD

We manufacture sample elements also with injection method with the use of simple, one-cavity moulds. This solution is the most expensive but also the most reliable one. With this method, you will receive a sample element with features identical to the ones set out in your design.

The physical verification of the correctness of the design, which we offer at Gieros, brings you savings – of your financial resources and our workload.

STAGE I DESIGNING

GO TO A DIFFERENT SAGE